- Get link

- X

- Other Apps

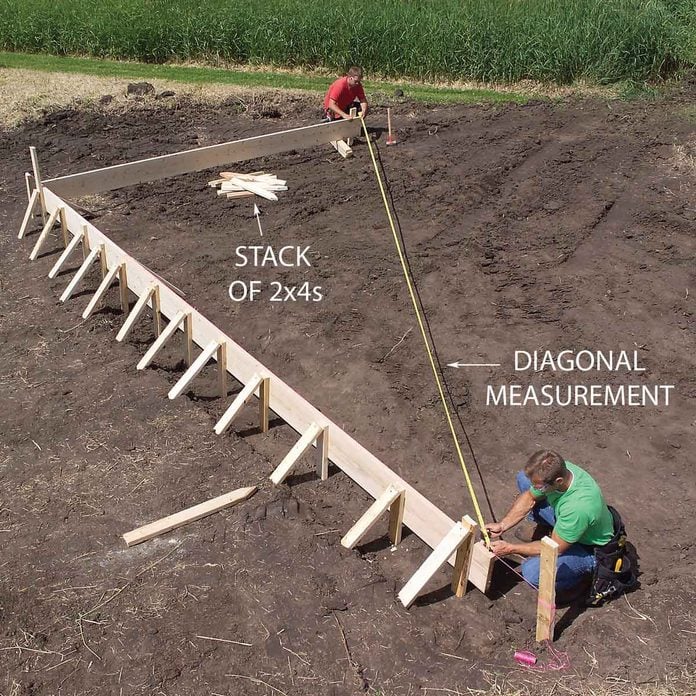

Besides the fact the GFRC is now the preferred method for professionals to create concrete countertops this also has the big disadvantage that you need a steel-topped casting table. Stake 4 inch 102 cm slabs a minimum of 32 inches 813 cm on center and deep enough to firmly support the form depending on the stability of the soil beneath the form.

How To Form Concrete Walls With Pictures Wikihow

How To Form Concrete Walls With Pictures Wikihow

2 x 4s and 34 forming plywood works best.

How to make concrete forms. We make sure the concrete is well placed on the bottom of the forms where there is a greater chance to form voids. Cut a 2x12 to length or splice it with a cleat for one side of the concrete forms and nail it to a corner stake. For a 5-in-thick slab with thickened edges which is perfect for most garages and sheds 2x12 boards work best.

Start by choosing straight form boards. Large-diameter or tall forms may re q u i re use of a crane. The smaller Sawzall does a better job.

For thicker slabs decrease your stake spacing a 12 inch 305 cm slab will need to be staked no more than 24 inches 610 cm on center. The plywood needs to. Several molds will make the concrete work go a lot.

If they will be reused then use treated lumber. Alternatives to Wooden Concrete Forms. Cressets Crete-Lease 880 VOC is the form release agent because it is designed for metal surfaces.

Big vibrators can blow out the bottom of the foam forms. However if youre planning on making a lateral concrete structure such as a support post or anchor you wont be able to rely on a wood-based mold. The best form for a particular project is often a function of the pour size the amount of concrete the form needs to retain and the pressure or weight that will be pushing against the form.

How to Build Concrete Forms. The 2 x 4s should be No2 kiln dried pine simply because it is cheap easy to work with and holds nails very well. For GFRC casting you can simply create melamine boxes.

Make concrete molds for wet casting form liners concrete stamps and GFRC decorative structures and panels. The paste composed of portland cement and water coats the surface of the fine small and coarse larger aggregates. A wooden concrete form can often do the job when it comes to making a flat slab.

This crew coats the entire inside of the form boards with an evaporation retardant. How to build a form for concrete slabform for concrete build how toFormForConcrete Build HowToBuild Concrete HowTo F. Because fiber tubes a re lightweight 3 to 41 2 pounds per lineal foot for a 16-inch-diameter form they often can be lifted man-u a l l y.

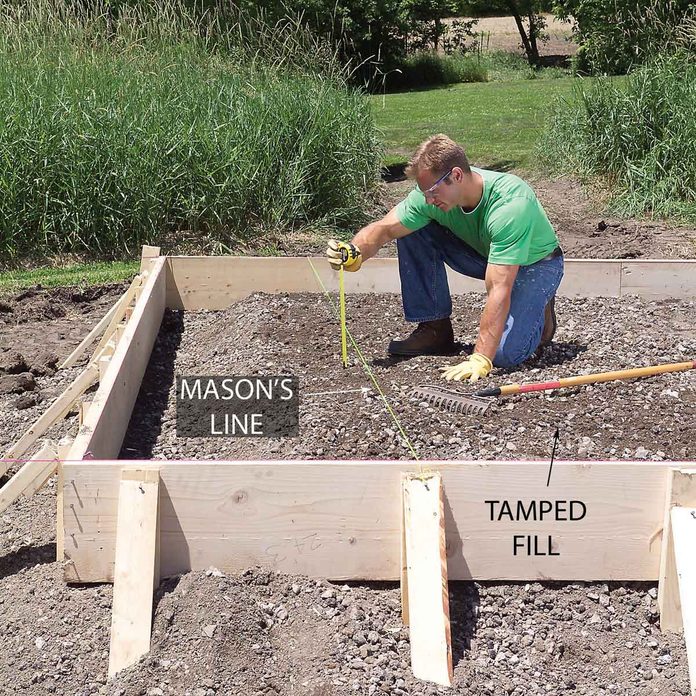

For example the typical concrete forms used for flatwork such as a patio driveway sidewalk or road range in height from 3 to 12 inches. Through a chemical reaction called hydration the paste hardens and gains strength to form the rock-like mass known as concrete. The retardant keeps the surface workable longer and acts as a form release preventing the concrete from sticking to the form boards when the form is dismantled.

Level the 2x12 and nail it to the second corner stake. How Concrete is Made In its simplest form concrete is a mixture of paste and aggregates or rocks. To strip fiber tubes make one or two full-length vertical cuts in the form with a power saw and pull off the form.

Id suggest building forms for the walls base from 2 X 8 boards and then using the same lumber for the block forms after the footer is done. The form will be lightweight and strong.

Forming Concrete Steps Concrete Construction Magazine

Forming Concrete Steps Concrete Construction Magazine

Beginner S Guide To Concrete Forming Doityourself Com

Beginner S Guide To Concrete Forming Doityourself Com

Concrete Forms And Pouring A Concrete Slab Diy Family Handyman

Concrete Forms And Pouring A Concrete Slab Diy Family Handyman

Finkbuilt Blog Archive How To Make Concrete Steps

How To Make A Concrete Seat Buildeazy Concrete Diy Projects Concrete Projects Concrete Diy

How To Make A Concrete Seat Buildeazy Concrete Diy Projects Concrete Projects Concrete Diy

Concrete Forms And Pouring A Concrete Slab Diy Family Handyman

Concrete Forms And Pouring A Concrete Slab Diy Family Handyman

How To Build Concrete Forms Youtube

How To Build Concrete Forms Youtube

Concrete Forms And Pouring A Concrete Slab Diy Family Handyman

Concrete Forms And Pouring A Concrete Slab Diy Family Handyman

How To Make A Concrete Fire Feature How Tos Diy

How To Make A Concrete Fire Feature How Tos Diy

Make Concrete Garden Boxes Part 1 Complete Precast Form Build Man About Tools Concrete Garden Garden Boxes Garden Boxes Diy

Make Concrete Garden Boxes Part 1 Complete Precast Form Build Man About Tools Concrete Garden Garden Boxes Garden Boxes Diy

How To Build A Straight Form For Concrete 6 Steps With Pictures

How To Build A Straight Form For Concrete 6 Steps With Pictures

Part One Preparing The Forms For Concrete Youtube

Part One Preparing The Forms For Concrete Youtube

Concrete Forms Forming Concrete With Wood Forms Youtube

Concrete Forms Forming Concrete With Wood Forms Youtube

Comments

Post a Comment